The Ins-and-Outs of CVT

11.10.2017

Public concern and increasing regulations surrounding environmental issues, such as CO₂ emissions, are making it important for car makers to improve the fuel efficiency of the vehicles they manufacture and market to the world. A wide array of transmission technology is being employed towards this including, but not limited to, continuously variable transmissions (CVT).

A continuously variable transmission (CVT) is an automatic transmission that can change seamlessly through a continuous range of effective gear ratios. In a car equipped with a CVT, there are no noticeable gear shifts unlike a regular transmission, where engine speed drops during the shift from a lower to a higher gear. That drop in RPM during shifts can put the engine speed below the RPM range where it makes power. In a CVT, the drop in RPM never happens.

More than any other transmission, a CVT relies on the performance of the fluid for its successful operation. Using a special CVT Fluid is critical in order to provide and maintain the required high metal-to-metal friction performance.

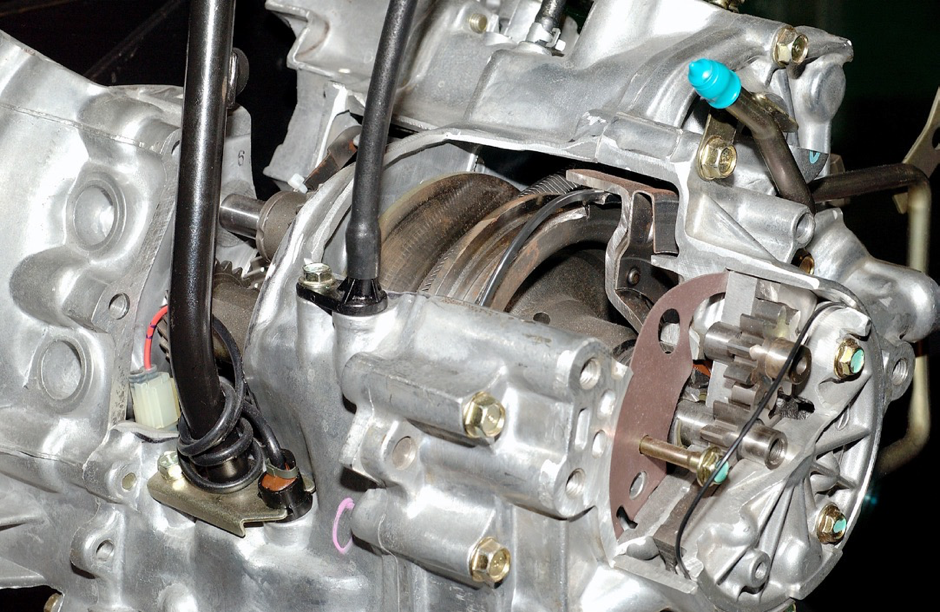

It is important to understand how the CVT functions in order to know why a conventional automatic transmission fluid (ATF) is not suited for use in a CVT. The required functions of ATF and CVT fluids are fundamentally different. The heart of a CVT consists of a variator with two pulleys, each built up of two conical, adjustable sheaves, around which a metal push belt or chain is looped. The torque is transmitted by the metal-to-metal frictional force generated between the pulley and the belt or chain. With high metal-to-metal friction, it is also essential to minimize wear between those elements. While CVT fluids deliver high metal-to-metal friction to allow CVTs to be used in the highest torque applications, a conventional ATF delivers low metal-to-metal friction which can lead to belt slippage, wear and severe damage to the pulley and the belt of the chain.

Shear stability is even more important for CVT fluids than for conventional ATF because of the high pressure pumps that are used in CVT applications. In addition to these specific requirements, CVT fluids must also offer advanced wear protection – particularly to control fatigue and sliding wear.

CVT fluids must also provide extended anti-shudder durability to enable aggressively slipping clutch operation, used by some designs for fuel efficiency, without reducing metal-to-metal friction. They must also deliver good oxidation stability, air release capability and paper-to-metal friction.

Due to the specific fluid functions each transmission requires, there is a high risk of mechanical damage that could occur in case of an accidental mismatch of fluid in the transmission. In some cases, the transmission could fail due to improper friction modifiers that transmissions are exposed to. It is crucial to drain and flush out the incorrect fluid filled in the transmission, in the case where an incorrect fluid is used.

Totachi CVT Fluid is a universal, 100% synthetic work fluid for variable transmissions. Engineered on the basis of exclusive technology from highly stable base oils of Group III & Group IV (PAO) and a combination of anti-wear and anti-oxidizing additives together with unique friction agents, the Totachi CVT formulation provides maintenance of effective operating temperature and accurate transfer of torque, prevents belt or chain slippage in transmission and reduces vibration. The product does not cause corrosion of details, made of nonferrous metals and does not have adverse effect on gaskets and elastomer seals that are typically used in car automatic transmissions.

Totachi CVT Fluid is recommended for use in all belt-CVT and chain-CVT applications. However, it is not recommended for Toroidal CVTs.

With the help of Lubrizol Corporation, here are some test results comparing Totachi CVT Fluid against Nissan NS-2 and Honda HMMF. Source: Lubrizol Corporation, 2011.

Characteristic Comparison Test

The analysis shows that Totachi CVT Fluid has superior shear stability, metal-to-metal friction resistant, anti-shudder performance, and higher extreme pressure/anti-wear protection compared to Nissan NS-2 and Honda HMMF fluids.

CVT Belt Box Durability Test

The wear analysis of belt elements and pulleys in this durability test shows that Totachi CVT Fluid has superior metal-to-metal wear protection as compared to both the Nissan NS-2 and Honda HMMF fluids.

For more information (and the suitability for use), please click the download link for the Technical Data Sheet (TDS) for Totachi CVT Fluid.

For more enquiries on Totachi CVT Fluid, kindly consult our distributors in your country or email us at info@totachi.comfor assistance.

Stay tuned for more updates!