TOTACHI Hyper series is specifically formulated for the latest generation of Asian gasoline engines, including turbocharged gasoline direct injections (TGDI), hybrid electric vehicles (HEV), plug-in hybrid electric vehicles (PHEV), range-extended electric vehicles (REEV), battery-assisted hybrid vehicles (BAHV), Extended Range Electric Vehicles (EREV), and all other vehicles that frequently operate under challenging urban conditions characterized by frequent "Stop-Start" modes. This oil is meticulously crafted to meet the highest standards, complying with the latest API SP and ILSAC GF-6A specifications, ensuring optimal performance and protection for these advanced engine technologies.

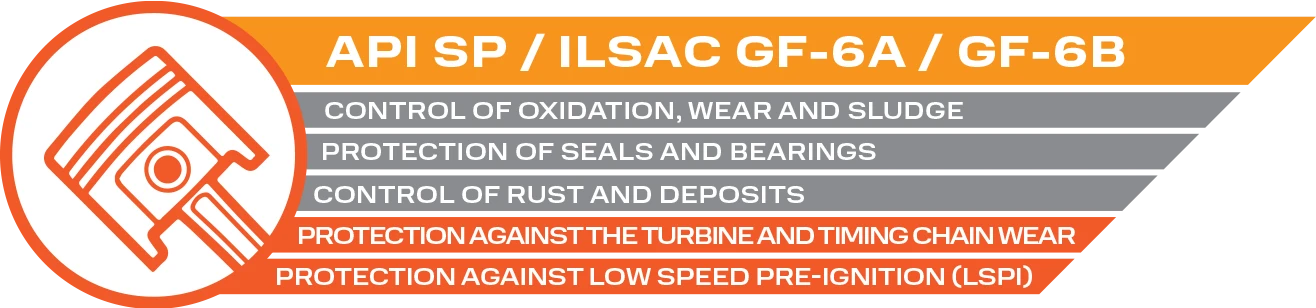

New engine technologies impose increased requirements on oil formulas and technologies to meet API SP and ILSAC GF-6A specifications:

API SP is the newest standard for gasoline engine oil, established to fulfill crucial demands of modern engines. This includes protection against chain wear, low-speed pre-ignition (LSPI), and deposit formation. API SP serves as the foundation for the ILSAC GF-6 specification which address fuel economy. Available in different viscosity grades and backward compatible with the previous generation.

ILSAC GF-6 is the latest engine oil quality standard by the International Lubricant Standardization and Approval Committee, aimed at improving fuel efficiency and improving the performance of the passenger car engines. This new standard replaces the current ILSAC GF-5 standard. Each new standard level is backward compatible with the previous generation.

ILSAC GF-6A: Backward compatible with SAE 0W-20, SAE 5W-20, SAE 0W-30, SAE 5W-30 and SAE 10W-30, but not SAE 0W-16

ILSAC GF-6B: New standard ONLY for SAE 0W-16, developed to meet the requirements of specific modern engines.

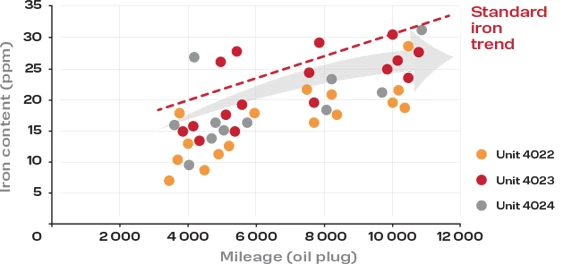

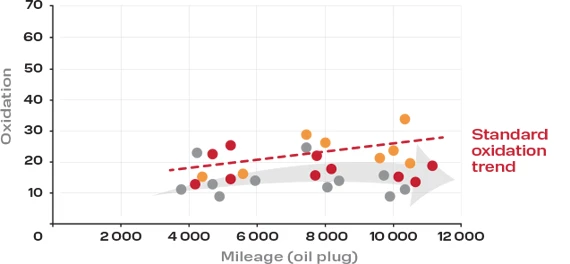

50 cars of various brands with different atmospheric engines and turbocharging took part in testing.

The total mileage during testing exceeded 3 000 000 km.

Each car underwent engine disassembly at the end of the field test.

Very clean bottom and piston head. Good control of piston deposits during oil change interval of 20 000 km

Benefits: Reduction of engine knock. Reduced fuel consumption and oil top ups. Reduction of harmful exhaust gases emissions.

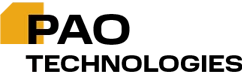

A clean shaft and a central hole in the housing

Benefits: protection from high temperatures and risk of cocking

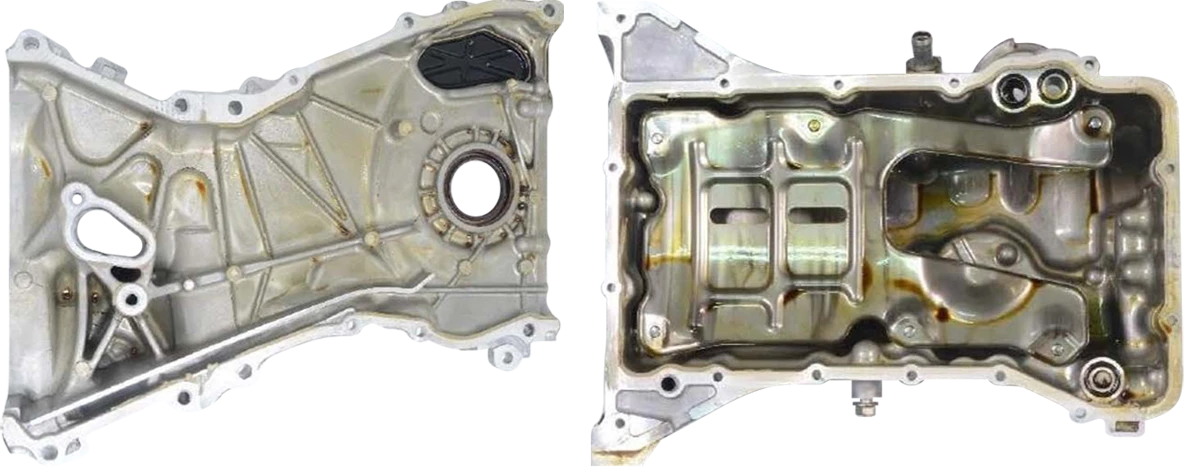

Excellent sludge control performance

Benefits: reducing possibility of poor ventilation, high oil temperature caused by heavy sludge, clogged oil filters, oil starvation leading to serious engine failures